Academic Opportunities - Energy Conservation Measures for a Sustainable Future

November 1, 2021

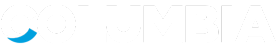

Existing Labs can become Sustainable

To meet carbon footprint goals, comply with new energy-reduction requirements, or to be responsible global citizens, many institutions are working to reduce their production of greenhouse gasses significantly. Through a series of targeted energy conservation measures (ECM’s), one of our academic clients is taking aim at their largest energy-user on campus. This major lab facility will undergo approximately $10.3M worth of building-wide mechanical system modifications and implement a new energy management system resulting in hefty energy savings while dramatically reducing their overall carbon footprint. Some of the key statistics are in the diagram above.

Communicating for Success

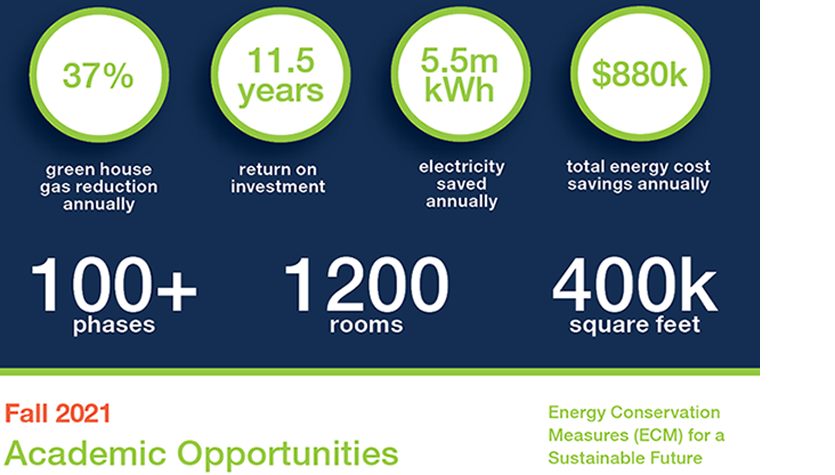

The key to this effort is achieving aggressive energy goals while mitigating any significant disturbances to the important work of the researchers. In addition to a consistent process for communication, Columbia is taking the following measures to ensure minimal disruptions and no surprises:

- Detailed Scheduling: Researchers are rightfully reluctant to give up their lab space for any length of time. With that in mind, we’ve created a schedule with nearly 100 phases for 1,200+ rooms that establish levels of impact for the end-users through color-coding:

- Green work can be ongoing with minimal disruption

- Yellow means the space can be occupied, however, some disruptions and short periods of displacement are possible

- Red space will need to be vacant for safety reasons and proper completion of short-term work

- This fine-tuned detail of durations makes it easier for project management staff to communicate with the users and gain buy-in for short, pin-pointed interruptions instead of ongoing uncertainty and displacement.

- Design-Assist: To maintain detailed accuracy in our schedule, we obtained consistent input by partnering with a trusted mechanical subcontractor during the design and preconstruction phase for durations and impacts of specific tasks. The client saw the critical value of engaging the right partner during design to help ensure our scheduling was in alignment with the actual availability of on-site staff to complete the specific scope in the time-frames planned.

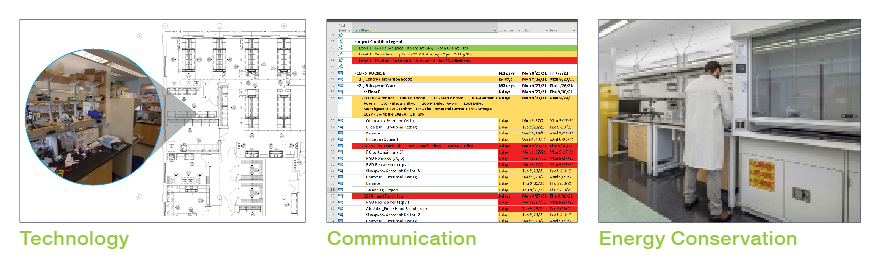

- OpenSpace: In a sensitive lab facility such as this, access to spaces to review site conditions must be minimized. Our Virtual Construction team captured the entire building with 360° imagery so that all team members can access site information virtually at any time without unnecessary interruption to vital research. This communication tool is invaluable during construction when site access is restricted and will be a continual benefit throughout and after completion of construction.

- In-house MEP: The scope of work for this project is all about mechanical systems, fume hoods, building controls, and energy efficiency. Our in-house MEP Team has been integral in developing the design, budgeting, and ongoing support throughout the submittal process, construction, and project closeout. With many years of experience, our team brings a wealth of knowledge to resolve constructability issues and work through options to help meet budget targets.